Olaroz Lithium Facility Production Update

Brisbane, Dec 4, 2015 AEST (ABN Newswire) - Orocobre Limited ( ASX:ORE) (

ASX:ORE) ( TSE:ORL) (Orocobre or the Company) wishes to advise on progress at the Olaroz Lithium Facility.

TSE:ORL) (Orocobre or the Company) wishes to advise on progress at the Olaroz Lithium Facility.

Olaroz Lithium Facility Operations Update

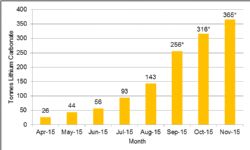

- Production of 365 tonnes of lithium carbonate was achieved in November, an increase of 49 tonnes over October.

- Improvements made to heat distribution systems throughout the plant including joining both main boilers to the same circuit and installing special diffusers in the crystallizers.

- Installation of additional heat exchangers, flocculation system, second centrifuge and additional boiler on track as per previous advice.

- Breakeven point guidance of December 2015 unchanged.

Production at the Olaroz Lithium Facility continued to increase in November with 365 tonnes of lithium carbonate produced, an increase of 49 tonnes on October. Of this production, 53 tonnes was recovered from within the purification circuit. During the first part of the month a supply chain issue was encountered with limitations in carbon dioxide (CO2) supply. This reduced production during the period by approximately 70 tonnes that would have been produced in the month. Without this limitation, production would have been in the order of 435 tonnes. To solve this issue and mitigate future risk, arrangements have been made to add an additional carbon dioxide supplier to supply the facility.

De-bottlenecking progress

Since the last update, progress continued on the de-bottlenecking program.

- Heat Exchangers, Absorption Circuit Cooling, and Flocculation:

During the month, improvements in operating practice have resulted in significantly improved availability of the heat exchangers which cool the feed slurry prior to the absorption reactors in the purification circuit. A recirculation line back to the plant feed pond has also been installed which results in the cooling of the purification circuit feed slurry being independent of the operations of the primary lithium carbonate circuit resulting in more stable cooling temperatures. The additional heat exchangers to be installed in parallel to the existing heat exchangers are expected to be installed in December as planned and will allow a heat exchanger (which cools the feed slurry to the purification circuit) to be taken offline for cleaning without interruption of cooling of the feed slurry. In the meantime, the flocculation operation to settle the suspended magnesium, sodium boron and calcium salts in the concentrated brine feed pond will be commissioned in early December.

- Magnesium and Calcium removal by Centrifuges:

The second centrifuge is currently being installed and is 75% complete. This second centrifuge will allow nameplate flow rate to be achieved and will be commissioned in early December.

- Boiler Increase and Heat Distribution:

During November, the distribution systems of the two steam boilers were joined permitting better heat distribution throughout the plant. The additional boiler is currently being installed and will be linked into the current steam distribution system prior to final piping and circuit commissioning in early January. The increase in boiler capacity will permit the crystallizers to operate at design temperatures and full production capacity.

Production Guidance and Brine Inventory

The Olaroz Lithium Facility will reach breakeven point on an operating cost basis (net of taxes paid or reimbursed), when production reaches approximately 650 tonnes per month, subject to variability in final average sales price. This production rate (~21-22tpd) is still expected to be achieved during December 2015.

All de-bottlenecking projects impacting production are expected to be completed by early to mid January 2016 permitting the plant to enter the final stage of ramp up and achievement of the nameplate production run rate. The timing of achievement of the nameplate production run rate is dependent upon the successful optimisation of operating practice and process controls once the debottlenecking rectifications are complete. There are no material changes to the capital cost estimates previously announced.

Sales Orders

Commercial shipments of lithium carbonate have been and continue to be dispatched from the Olaroz Lithium Facility to Europe, Asia and the USA. All product that has been reported as produced is saleable product and has been sold or committed to a customer's purchase order. As previously advised samples have been provided to both industrial and battery sector customers.

Market Conditions

Prices in recent times have been steadily increasing to over US$6,000/tonne with further increases expected into CY2016 and beyond as lithium market conditions continue to tighten and higher pricing is expected into 2016 based on current negotiations. Strong market demand and supply side constraints are resulting in continued upward pressure on market prices for lithium carbonate. FMC Corporation ( NYSE:FMC) announced a 15% price increase in September for lithium products, effective 1st October 2015. SQM (

NYSE:FMC) announced a 15% price increase in September for lithium products, effective 1st October 2015. SQM ( NYSE:SQM) also recently reported higher average prices in 2015 with an average price for the first 9 months of 2015 of ~US$5,700/tonne.

NYSE:SQM) also recently reported higher average prices in 2015 with an average price for the first 9 months of 2015 of ~US$5,700/tonne.

Managing Director Comments

Managing Director, Richard Seville, said, "The progress at Olaroz continues to be positive with the completion of debottlenecking activites drawing closer. Our "know how" and operating practices continue to improve and we are constantly encouraged and motivated by the increasing production levels and very favourable market conditions."

To view figures, please visit:

http://media.abnnewswire.net/media/en/docs/ASX-ORE-896038.pdf

About Orocobre Limited

Orocobre Limited is listed on the Australian Securities Exchange and Toronto Stock Exchange (

Orocobre Limited is listed on the Australian Securities Exchange and Toronto Stock Exchange ( ASX:ORE) (

ASX:ORE) ( TSE:ORL) (OTCMKTS:OROCF), and is building a substantial Argentine based industrial chemicals company through its portfolio of lithium, potash and boron assets. In partnership with Toyota Tsusho Corporation (TTC) and JEMSE, Orocobre has built and is now operating the world's first commercial, brine-based lithium operation constructed in approximately 20 years.

TSE:ORL) (OTCMKTS:OROCF), and is building a substantial Argentine based industrial chemicals company through its portfolio of lithium, potash and boron assets. In partnership with Toyota Tsusho Corporation (TTC) and JEMSE, Orocobre has built and is now operating the world's first commercial, brine-based lithium operation constructed in approximately 20 years.

In 2018 Orocobre announced the Stage 2 Expansion of its flagship Olaroz Lithium Facility in Argentina. The Stage 2 Expansion will add 25,000 tpa of lithium carbonate production capacity, taking full production and capacity to 42,500 tpa of lithium carbonate for sale to industrial, technical and battery markets, positioning Orocobre as one of the world's largest and lowest cost lithium chemicals producers.

Additionally, Orocobre and Toyota Tsusho Corporation have commenced construction of the 10,000 tpa lithium hydroxide plant in Naraha, Japan. The construction of the Naraha Lithium Hydroxide Plant will further cement Orocobre's position as a global lithium chemicals producer operating at the bottom quartile of the lithium cost curve. This new hydroxide plant will be the first of its kind in Japan and will provide Orocobre product diversification suitable for different battery technologies and the potential for significant margin growth on our primary lithium carbonate being converted to battery grade lithium hydroxide.

| ||

|