Altech Submits Mining Proposal and Mine Closure Plan

Perth, Dec 2, 2016 AEST (ABN Newswire) - Altech Chemicals Limited ( ASX:ATC) (Altech/the Company) is pleased to advise that further to its 20 May 2016 announcement of the grant of mining lease M70/1334 at Meckering, Western Australia the Company has now submitted a mining proposal (MP) and mine closure plan (MCP) to the Department of Mines and Petroleum (DMP). The submission marks the next stage of development of the Company's proposed Meckering kaolin mine, which will provide feedstock for its proposed Malaysian high purity alumina (HPA) plant.

ASX:ATC) (Altech/the Company) is pleased to advise that further to its 20 May 2016 announcement of the grant of mining lease M70/1334 at Meckering, Western Australia the Company has now submitted a mining proposal (MP) and mine closure plan (MCP) to the Department of Mines and Petroleum (DMP). The submission marks the next stage of development of the Company's proposed Meckering kaolin mine, which will provide feedstock for its proposed Malaysian high purity alumina (HPA) plant.

Highlights

- Meckering mining proposal and mine closure plan submitted to DMP

- Proposed mining activity is a simple quarry style operation, no drill and blast required

- Two month mining campaign first 3 years kaolin feedstock

- Year-round kaolin container loading operation at Meckering site

- Containers shipped to HPA plant in Johor via port of Fremantle, Western Australia

At Meckering, Altech is planning to mine approximately 140,000 tonnes of kaolin once every three years; mining will take place in short two-month mining campaigns. The resultant raw kaolin ore will be stockpiled, then containerised into standard shipping containers at the rate of approximately 42,055tpa and shipped to Johor, Malaysia via the port of Fremantle, Western Australia.

The Company's Meckering mining lease M70/1334 contains a Mineral Resource estimation of 12.7 million tonnes @ 29.5% Al2O3 (alumina) in the minus 300 micron kaolin fraction with a cut-off grade of 25% Al2O3 (refer Table 1 in the link below). This represents over 250 years of feedstock supply for the Company's proposed HPA plant. Based on the Mineral Resource, a maiden Ore Reserve of 1.2 million tonnes @ 30% Al2O3 (alumina) in the minus 300 micron kaolin fraction with a cut-off grade of 25% Al2O3 was estimated (refer Table 1 in the link below). The Ore Reserve will support an initial 30-year mine life based on 4,000tpa of HPA production. Mine development at Meckering is expected to commence in approximately 12 months, subject to funding and approvals.

Altech managing director Mr Iggy Tan said, "The Company is delighted to have rapidly progressed to the next stage of development at Meckering, with the submission of a mining proposal and an associated mine closure plan in preparation for mine development in 2017.

"The submission marks another important step in the development of the Company's HPA project", Mr Tan concluded.

Mining Proposal

The relatively low annual tonnage of kaolin feedstock required for the proposed HPA plant means that the Meckering mine will be a simple quarry style operation. No blasting is required due to the highly weathered nature of the kaolin mineralisation. The mine plan, pit design and associated Ore Reserve for the proposed Meckering mine confirms a 30-year mine life at Meckering, providing over 1.2Mt of high-quality, alumina-rich kaolin feedstock to supply the proposed HPA plant.

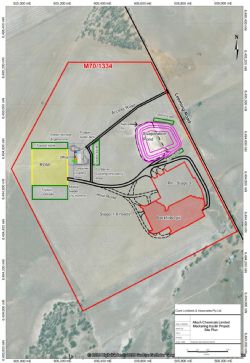

Proposed Site Layout

The Company's proposed Meckering site layout was designed to optimise the proposed mining, haulage, waste placement, water storage and site rehabilitation. The run of mine (ROM) stockpile is designed to hold around 140,000t of material and will be located directly adjacent of the kaolin mine. Mined ore will be hauled directly from the mining area to the ROM stockpile. A lay down yard adjacent to the ROM will be used to fill standard 20' containers, which will be loaded onto trucks for transportation to Fremantle port.

A conventional truck/excavator open pit mining method was selected due to the near surface presence of the kaolin ore. The flat-lying nature of the deposit will allow mining to proceed at a constant strip ratio.

The Meckering container loading facility will consist of a:

- conventional front end wheel loader (3.5m3 bucket), which will be used to reclaim the kaolin ore from the ROM stockpile;

- trommel unit, which will screen the kaolin ore and reject any material >12mm;

- telescopic conveyor unit that will extend the full length of a 20' container and slowly retract during loading, enabling consistent distribution of the kaolin ore along the length of the container;

- loading shed to house the above screening equipment; and

- an office space, which includes lunch room and toilet facilities.

Once loading of the container is complete, it is lifted and stacked in the loading yard by a heavy-duty forklift. This forklift is also utilised for truck loading and unloading empty containers.

Site Facilities

The Meckering container loading facility is a two-man operation that is intended to operate on weekdays during daylight hours throughout the year. The facility consists of a loading shed, an office/lunchroom and toilet facility, and an area designated for the loading and unloading of containers. Potable water is trucked to the site and stored in a potable water tank. Electrical requirements are met by a small diesel generator. Diesel storage facilities and bowser allow for refuelling of mobile equipment, light vehicles and generators.

Transport Route

The Company's Meckering tenement M70/1334 is located approximately 130km east of Perth and 8km south-east of the town of Meckering in the Wheatbelt region of Western Australia. The tenement is accessible via a number of well-maintained gazetted public roads, which link directly to the Great Eastern Highway (as per Figure 4 in the link below). The distance from the Meckering site to the Fremantle port is approximately 150km. Haulage of approximately 42,000tpa of containerised kaolin ore from the Meckering site will be undertaken by Altech's freight partner, Seatram.

To view tables and figures, please visit:

http://abnnewswire.net/lnk/KTR000GC

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|