ALTECH - HPA PLANT SITE LAYOUT AND BUILDING DESIGN FINALISED

Perth, Nov 6, 2018 AEST (ABN Newswire) - Altech Chemicals Limited (Altech/the Company) ( ASX:ATC) (

ASX:ATC) ( A3Y:FRA) is pleased to announce that it has now finalised and "locked" the site layout and building design for its proposed Malaysian high purity alumina (HPA) plant. The final layout and design incorporates results from the recently completed site geotechnical survey and feedback from pre-construction consultation meetings between SMS group GmbH (appointed EPC contractor), local authorities, and Malaysian permitting consultant WKL & Associates. The final design is the basis for the submission of a development order application and the commencement of stage 1 construction.

A3Y:FRA) is pleased to announce that it has now finalised and "locked" the site layout and building design for its proposed Malaysian high purity alumina (HPA) plant. The final layout and design incorporates results from the recently completed site geotechnical survey and feedback from pre-construction consultation meetings between SMS group GmbH (appointed EPC contractor), local authorities, and Malaysian permitting consultant WKL & Associates. The final design is the basis for the submission of a development order application and the commencement of stage 1 construction.

Highlights

- HPA plant site layout and buildings design finalised

- Incorporates results from geotechnical ground survey

- Construction development order application

- Stage 1 construction to commence

The final site layout (see Figure 1) comprises three (3) production buildings:

- Building 1: Kaolin Beneficiation

- Building 2: Leach & Neutralisation

- Building 3: HPA Production & HCL Recycle Plant

There are four (4) ancillary buildings:

- Administration and Process

- Workshop and Stores

- Guardhouse and First Aid

- Electrical Substation

Detailed HPA Plant Layout Information

All processing equipment will be installed in one of the three production buildings. The HPA production buildings have been laid out on the 4Ha site in Johor, Malaysia to closely reflect the order of the kaolin to HPA chemical process illustrated in the in the Company's process flow sheet. The HPA manufacturing process will commence with kaolin beneficiation; then filtration and meta-kaolin conversion in Building 1; kaolin leach, leach residue and waste water neutralisation circuits in Building 2; followed by crystallisation, roasting, calcination and HPA finishing in Building 3. Building 3 includes a segregated structure within which the hydrochloric acid (HCI) recovery and recycling plant will be located.

The Administration and Process building will be the central location for plant operational management and administration. The building is separated into halves, an administration wing and a process wing. The administration wing will accommodate HPA site general management, process engineering, finance and administrative staff. Included in the administration wing is a conference room, training rooms, meeting rooms and lunchroom facilities.

The process wing will be the location for the site's central control room, from where the operation of the entire HPA plant will be monitored and managed. In addition, the process wing will accommodate the site's laboratory; process control and programming engineers; operator change rooms; and will also have separate lunchroom facilities.

The Workshop and Stores building will be the location for the storage of all minor equipment and spare parts; the conduct of valving and instrument maintenance and for all fabrication activities. A dedicated stores area has been allowed for to accommodate the delivery, receipt and storage of spare parts, consumables and reagents.

The building also includes office space for site maintenance and purchasing teams.

A Gatehouse and First Aid building will be the single point of entry to the HPA site. The building will include a guardhouse that will be manned 24 hours a day and site access beyond the gatehouse will be only via a cardentry turnstile. A visitor waiting room, meeting room and lunchroom are included in the building, as is a dedicated first aid room and ambulance parking bay.

Altech managing director Mr Iggy Tan said "the HPA plant site layout and building designs are of the highest calibre. Naturally, the designs are to international standard and of a quality expected from our appointed German EPC contractor SMS group. The next step of project development is application for a development order from local authorities. We are currently waiting for a land sub-title number (PTD number) to be issued for the ~4HA site, so that the development order can be submitted. Once the development order is issued, the staged mobilisation of various sub-contractors, most of which are Johor based, will commence." Mr Tan concluded.

To view tables and figures, please visit:

http://abnnewswire.net/lnk/G34R4983

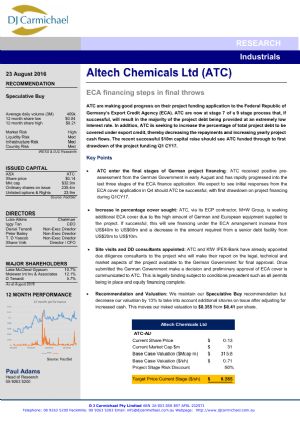

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|