Quarterly Activities Report

Quarterly Activities Report

Perth, April 17, 2020 AEST (ABN Newswire) - During the March 2020 quarter, Cyprium Metals Limited ( ASX:CYM) completed 4,902 metres of Reverse Circulation ("RC") drilling at the Cue Copper Project.

ASX:CYM) completed 4,902 metres of Reverse Circulation ("RC") drilling at the Cue Copper Project.

RC drilling at the Eelya South prospect returned an intersection of 3.0m @ 3.78% Cu in drill hole 20ESRC014 which also included 6.68 g/t Au and 81.0 g/t Ag from 59m (refer to Figures 1 and 2*).

This high-grade copper/gold southern Eelya South intersection in drill hole 20ESRC014 was drilled to test a structure, previously identified at Eelya South in the 1990's which returned an intersection of 2.0m @ 10.12% Cu, 3.19 g/t Au and 92.0 g/t Ag from 40m in drillhole ERC19 (refer to Figure 2*). These high-grade copper/gold drilling intersections are located less than 1 kilometre to the south of the surface sampling programme that was previously announced in November 2019. The follow up RC drilling as outlined in Figure 2* at the prospective Eelya South tenement was completed by the end of the quarter.

Further extensional RC drilling was completed by the end of the quarter at the Hollandaire deposits and the results of these drilling activities will be announced during the June 2020 quarter.

Metallurgical Test-Work

Metallurgical column test-work continued during the quarter on the massive and semi-massive sulphides samples from the Hollandaire and Hollandaire West prospects at the Cue Copper Project. This test-work has been undertaken to determine the optimal copper extraction process for our unique methodology, which has leached copper rapidly into solution as previously announced in October and November 2019, February and March 2020.

The primary leach solution ("PLS") produced from the metallurgical column test-work has been processed in an electrowinning ("EW") cell (refer to Image 1*) to produce cathode copper metal plates (refer to Image 2), which were then stripped from the cathodes to complete the processing cycle through to its final product of high purity copper metal plate (refer to Image 3*).

A full metallurgical processing cycle has been completed starting from drilling the mineralisation, to crushing and leaching through to plating copper as a proof of concept of our low-cost treatment methodology. The Hollandaire material is very suitable for our methodology and it has outperformed the initial expectations.

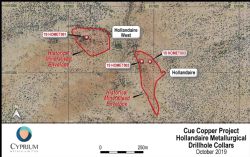

The metallurgical diamond drill programme that was completed in 2019 consisted of three holes for 320 metres into the mineralised envelope of the Hollandaire Prospect at the Cue Copper Project to provide representative samples for test-work to be undertaken (refer to Figure 3*).

The first hole in the metallurgical diamond drilling programme, 19HOMET001, was drilled into the Hollandaire West deposit and returned disseminated copper sulphide mineralisation. The second and third diamond drill holes in the programme, 19HOMET002 and 19HOMET003, targeted representative sections of the Hollandaire deposit and returned semi-massive to massive sulphide mineralisation. The results from the metallurgical diamond drill holes included:

- 10.4m @ 14.9% Cu in drill hole 19HOMET003 from 84.5m downhole including:

- 4.5m @ 21.9% Cu from 90.4m;

- 19.1m @ 1.3% Cu in drill hole 19HOMET002 from 85.9m downhole including:

- 6.4m @ 2.1% Cu from 98.6m;

- 27.9m @ 1.1% Cu in drill hole 19HOMET001 from 45.7m downhole including:

- 9.0m @ 1.6% Cu from 63.2m.

At the completion of drilling, core samples from the Cue Copper Project were received at the metallurgical laboratory which was crushed, split and assayed for multi-element grades.

Composites were then created for the Hollandaire deposit and the Hollandaire West deposit.

Hollandaire samples were composited from holes 19HOMET002 and 19HOMET003 to create two column samples, Columns A and B, with copper grades of 5.10% and 5.24% respectively.

Separately, the drill core from Hollandaire West, obtained from drill hole 19HOMET001, was composited for testing in a third column, Column C, with an average grade of 0.76% copper.

Diagnostic testing and mineralogical analysis were undertaken on the samples to determine the optimal parameters to use to undertake the column test-work.

The composites were then leached in separate columns with the resultant copper recovery over time under leach are presented in Graph 1*.

The results to date demonstrate an accelerated leach time for the extraction of copper metal into solution. The test-work on Column C, in particular, has demonstrated a more rapid leach than Columns A and B, which is a remarkable result that has been achieved after only 6 days.

The effect of the very short leach times on a potential Cue Copper Project is significant as it decreases the size of the heap leach pads, and consequently reduces the capital and operating cost requirements over the life of the operation.

The completion of the plating of copper from the PLS solution in an EW cell completes the process flow sheet for the extraction method of copper from the Hollandaire mineralisation. This is a very important milestone in the Company's aspirations to build a project at Cue. The proof of concept on the treatment of the mineralisation of Cue Copper Project to produce copper metal on site has now been completed.

The metallurgical test-work will now proceed to further optimise the process for the best outcome in terms of cost and efficiency that is possible. The data from this initial round of testwork is being used in the Cue Copper Project Scoping Study that the Company commenced during the March 2020 quarter.

Executive Director Barry Cahill commented "We are very pleased with the drilling programme at the Eelya South, in particular with the 3 metres at 3.78% copper intersection result whilst testing drilling targets in an area that previously been subject to very limited drilling activities. Our drilling activities have been focused on expanding the mineralised copper footprint at the Cue Copper Project to bring us closer to the critical mass required to advance this project to a developmental stage.

A full metallurgical processing cycle has now been completed, starting from the drilling of the mineralisation, to crushing and leaching through to plating copper as a proof of concept of our low-cost treatment methodology. The Hollandaire material is very suitable for our methodology and to produce such a clean copper plate of high purity so quickly is an extraordinary result. The parameters of the metallurgical test-work performed to date is forming part of the Scoping Study which is underway."

*To view the full report, please visit:

https://abnnewswire.net/lnk/CZB99362

About Cyprium Metals Ltd

Cyprium Metals Limited (ASX:CYM) is poised to grow to a mid-tier mining business and manage a portfolio of Australian copper projects to deliver vital natural resources, strong shareholder returns and sustainable value for our stakeholders. We pursue this aim, in genuine partnerships with employees, customers, shareholders, local communities and other stakeholders, which is based on integrity, co-operation, transparency and mutual value creation.

Cyprium Metals Limited (ASX:CYM) is poised to grow to a mid-tier mining business and manage a portfolio of Australian copper projects to deliver vital natural resources, strong shareholder returns and sustainable value for our stakeholders. We pursue this aim, in genuine partnerships with employees, customers, shareholders, local communities and other stakeholders, which is based on integrity, co-operation, transparency and mutual value creation.

![abnnewswire.com]()

Related Companies

Social Media

Share this Article

ASX:CYM) completed 4,902 metres of Reverse Circulation ("RC") drilling at the Cue Copper Project.

ASX:CYM) completed 4,902 metres of Reverse Circulation ("RC") drilling at the Cue Copper Project.  Cyprium Metals Limited (ASX:CYM) is poised to grow to a mid-tier mining business and manage a portfolio of Australian copper projects to deliver vital natural resources, strong shareholder returns and sustainable value for our stakeholders. We pursue this aim, in genuine partnerships with employees, customers, shareholders, local communities and other stakeholders, which is based on integrity, co-operation, transparency and mutual value creation.

Cyprium Metals Limited (ASX:CYM) is poised to grow to a mid-tier mining business and manage a portfolio of Australian copper projects to deliver vital natural resources, strong shareholder returns and sustainable value for our stakeholders. We pursue this aim, in genuine partnerships with employees, customers, shareholders, local communities and other stakeholders, which is based on integrity, co-operation, transparency and mutual value creation.