4N HPA's Application in Solid State Lithium-ion Battery

Perth, Feb 11, 2020 AEST (ABN Newswire) - Altech Chemicals Limited ( ASX:ATC) (

ASX:ATC) ( A3Y:FRA) is pleased to provide information regarding the possible use of high purity alumina (HPA) in the manufacture of a likely next generation of lithium-ion battery (LiB) - the solid state LiB. The Company has been frequently asked if 4N HPA will be used in future solid state lithium ion batteries where there are no ceramic coated separators.

A3Y:FRA) is pleased to provide information regarding the possible use of high purity alumina (HPA) in the manufacture of a likely next generation of lithium-ion battery (LiB) - the solid state LiB. The Company has been frequently asked if 4N HPA will be used in future solid state lithium ion batteries where there are no ceramic coated separators.

As an internal research project, Altech has reviewed and investigated more than one hundred separate research journal articles citing the use of high purity alumina in the development of solid state lithium-ion batteries. Based on this extensive research, Altech believes that 4N HPA will continue to be a key ingredient of future commercialised solid state lithium-ion batteries. Similarly, the amount of 4N HPA used is also likely to be higher than the amount used in the current ceramic coated separators.

Conventional lithium-ion battery

Lithium-ion is arguably the most advanced battery technology available today and since its initial commercialisation in 1991, the lithium-ion battery has helped facilitated the prolific growth of a vast range of portable electronic devices, electric vehicles and renewable energy storage options. LiB's are increasingly indispensable for our comfortable living today.

A conventional LiB cell consists of two solid electrodes (anode and cathode) that are separated by a pool of liquid electrolyte and a polymer separator sheet (see figure 1 on page 2*). The electrolyte provides the pathway via which lithium ions travel from anode to cathode (and visa-versa) during battery discharge and recharge. However, the liquid electrolyte is the LiB's "Achilles' heel", as this organic substance is highly corrosive and highly combustible and has a finite operating temperature. Although low-risk, LiB's are susceptible to intense flammability (fire and/or explosion) and corrosion should battery integrity be compromised by for example, overcharging, short-circuit, overheating or mechanical abuse (e.g. bent, cut, crushed etc.).

Also, an inherent challenge of using lithium within a battery is the propensity for dendrites, or branch-like growths of lithium metal, to occur when lithium ions collect in localised areas on the electrode surface, usually the anode. During the charge cycle, lithium ions move from cathode to anode and distribute unevenly on the anode surface. With each subsequent charge cycle, ions find the path of least resistance, causing them to collect in localised areas that protrude from the anode surface. This reduces battery life (because of a reduced number of active lithium ions), but is a significant safety concern as the protrusions can grow long enough to span the distance between the electrodes, causing an internal electrical short circuit and resulting in battery failure. Furthermore, short-circuiting often causes localised heating and, because of the liquid electrolyte with low thermal stability, the battery can rapidly heat and a thermal runaway can result.

Solid State lithium-ion battery

Alternatively, a future solid-state LiB has a non-liquid "solid state" electrolyte which appreciably improves battery safety and allows for significantly higher battery operating temperatures, plus the propensity for dendrite grown across the electrolyte is reduced. However, solid-state LIB's have their own challenges, most prominent is slower ion diffusion during battery discharge and re-charge, as the lithium ions must travel through the solid state electrolyte, as compared to a liquid.

The challenge of reduced ion conductivity in a solid state LiB is addressed by using a different material for the battery anode. The graphite anode that is used in a conventional LiB can be replaced by a lithium metal anode in a solid state LiB, as lithium metal can store 10 times more energy than graphite. Consequently the slower ion flow between anode and cathode in the solid state LiB is more than off-set by the sheer amount of energy transferred compared to a conventional LiB. This increased energy transfer results in a much higher battery operating temperature, a temperature that far exceeds what would be safe if a liquid electrolyte were used.

Replacing the liquid electrolyte with a solid one has the advantage of physically suppressing dendrite growth. Solid electrolytes also improve battery safety due to their superior mechanical and thermal stability when compared to liquid electrolytes. The ion conductivity of solid electrolytes is thermally dependent and increases with temperature, meaning they are well suited for high temperature applications. However, conductivity also decreases with temperature meaning the energy density of solid-state batteries decreases significantly in cold conditions, something that needs to be managed.

Among the different types of solid-state electrolytes, polyethylene oxide (PEO) solid electrolytes have been the most extensively studied. PEO solid electrolytes are blends of a lithium salt and a high molecular weight polymer containing Li+-coordinating groups.

Numerous research papers have been published and numerous patents have been granted. A recognised limitation of PEO solid electrolytes is the low ion conductivity at lower temperatures due to the crystallisation of the polymer. However, it has been demonstrated that by adding 4N high purity alumina (HPA) to the polymer as a filler or active material, the crystallisation temperature is lowered and the polymer remains amorphous, enabling it to maintain its ion conductivities at lower temperatures. The typical addition of 4N HPA to the PEO is around 10 to 15% w/w (weight for weight), and it addition to maintaining polymer conductivity the HPA particles: increase mechanical strength; improve cycling performance and reduces crystallinity of the polymer host.

Based on extensive research in the field, Altech believes that 4N HPA will continue to be a key ingredient of future commercialised solid state lithium-ion battery. The demand for 4N HPA will likely increase further with the future development of solid state lithium-ion battery technology.

*To view tables and figures, please visit:

https://abnnewswire.net/lnk/9O4E2UML

About Altech Batteries Ltd

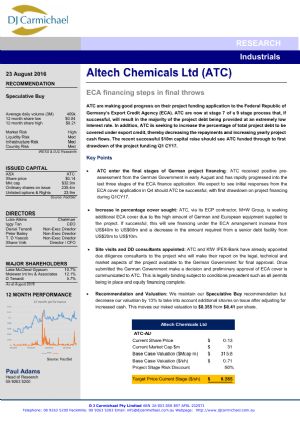

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|